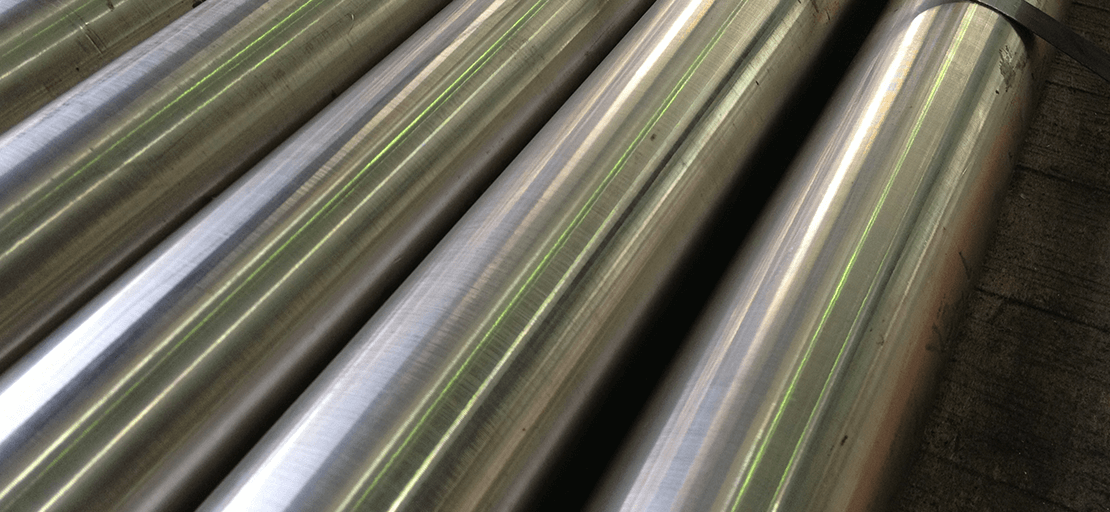

Copper-Nickel

Copper Nickel alloys have excellent corrosion resistance rates in sea water as well as a high resistance to crevice corrosion, stress corrosion cracking and hydrogen embrittlement.

It is also well known for its high resistance to biofouling through forming a thin protective surface layer during the initial stages of being subjected to sea water, which then provides an on going resistance thereafter.

Copper Nickel alloys are commonly used in seawater piping, condensers and heat exchangers in naval marine vessels, all in both 90-10 and 70-30 varieties.

CuNi material is offered by CF Booth in cast and machined billet/slab as well as forged bar/parts. To find out more information about the specifications available, choose from the datasheet buttons below to open the relevant PDF.

90/10 Copper Nickel 70/30 Copper Nickel High Strength CuNi - 835